Tootmine

Meie ettevõtte portfelli väljatöötamisel lähtuti kihisevate tabletide tehnoloogia nõuetest ning arvestades tootmistsükli tegelikke võimalusi ja farmaatsiaseadmete arendamise uusimaid uuendusi.

Portfelli kuuluvad kaasaegsed ravimvormid, näiteks kihisevad tabletid ja suu kaudu imendumiseks mõeldud suus dispergeeruvad tabletid, mida toodetakse eritingimustel, samuti närimistabletid ja muud tahked ravimvormid.

Meie praegune ravimiportfell sisaldab börsiväliseid (käsimüügis) geneerikaid. Lisaks on meil välja töötatud retseptiravimite ja bioloogiliste sarnaste ravimite uute geneerikute väljatöötamine.

PharmaEstica Manufacturing OÜ teostab ka private label’i ja lepingulisi tootmisprojekte.

Meie võimalused võimaldavad meil toota laia valikut toidulisandeid ja muid eritooteid. Meie toidulisandite portfell sisaldab mitmeid multivitamiinide ja mineraalide kombinatsioone täiskasvanutele, lastele ja sportlastele, sealhulgas taimset ekstrakti sisaldavaid tooteid. Toidulisandeid võib toota ka närimiskummide kujul.

| Ravimi nimetus | Toimeaine(d) ja tugevus | Ravimvorm ja pakendi suurus | Näidustused | Ravimi tüüp | Registreeritud | Allhanketootmine |

|---|---|---|---|---|---|---|

| Upstinon | Atsetüülsalitsüülhape 324 mg | Kihisevad tabletid № 10 | Valu. Palavik. | K | EE | |

| Asprovit+С | Atsetüülsalitsüülhape 400 mg, Askorbiinhape 300 mg | Kihisevad tabletid № 10, 20 | Nõrk valu. Palavik. | K | RU | |

| Asprovit | Atsetüülsalitsüülhape 500 mg | Kihisevad tabletid № 10, 12 | Nõrk valu. Palavik. Reumaatilised haigused. | K | EE | |

| Mucovit 600 | Atsetüültsüsteiin 600 mg | Kihisevad tabletid № 12, 10 | Röga lahtistamine. | K | EE; Protsessis- VN | AZ, GE, KZ, KG, MD, TJ, TM, UZ, UA; Protsessis- BY, RU |

| Mucovit 200 | Atsetüültsüsteiin 200 mg | Kihisevad tabletid № 10, 20, 24 | Röga lahtistamine. | K | EE; Protsessis- VN | AZ, GE, KZ, KG, MD, TJ, TM, UZ, UA; Protsessis-BY, RU |

| Padevix | Dekstrometorfaan 7,5 mg, Paratsetamool 300 mg | Kihisevad tabletid № 10, 20 | Samaaegne palaviku alandamine, nõrga valu leevendamine ja köha sümptomaatiline ravi. | K | EE |

| Toote nimi | Koostis | Toote vorm | Näidustus |

|---|---|---|---|

| PolliVital | Multivitamiinid rutiiniga | Suus dispergeeruvad tabletid | Multivitamiinid ja bioflavonoid rutiin rikastavad igapäevast toidusedelit. |

| OxiVital | Vitamiin E – 10 mg a-TE, Vitamiin C – 50 mg, Vitamiin A – 450 μg-RE, Seleen 20 μg | Suus dispergeeruvad tabletid | Aitab kaitsta rakke oksüdatiivse stressi eest ning aitab kaasa immuunsüsteemi tugevdamisele. |

| Resveratrol | Resveratrol 20 ja 40 mg | Suus dispergeeruvad tabletid | Tugevdav ühend. |

| PexVital | Multivitamiinid | Kihisevad tabletid | Vitamiinide lisaallikas. |

| SportActive | Vitamiinid, mineraalid | Kihisevad tabletid | Aktiivse eluviisiga inimestele ja sportlastele intensiivse kehalise koormuse ajal. |

Seadmed ja tehnoloogiad

Ettevõte toodab valmis ravimeid ja toidulisandeid järgmistes vormides: katmata tabletid, kihisevad tabletid, imemistabletid, keelealused tabletid, toimeainet prolongeeritult vabastavad tabletid, närimistabletid ja muud tahked vormid.

Ettevõte toodab valmis ravimeid ja toidulisandeid järgmistes vormides: katmata tabletid, kihisevad tabletid, imemistabletid, keelealused tabletid, toimeainet prolongeeritult vabastavad tabletid, närimistabletid ja muud tahked vormid.

Tablettide valmistamise tehnoloogilised protsessid viiakse läbi puhastes ruumides puhtusastmega D, kus temperatuuri ja niiskuse parameetritele on sätestatud spetsiaalsed eritingimused, et tagada ravimitele nõutav kvaliteet.

Tablettide peamine tootmismeetod on pulbrilise tableti segu, sealhulgas mikrograanulite, otsene kokkupressimine. Mikrograanulid on toodetud granulaatoris Herbert Hüttlin Ventilus V200.

Herbert Hüttli Ventilus V200 granulaatori tehnoloogia põhineb keevkihi granuleerimismeetodil, millega on võimalik saavutada soovitud omadustega graanuleid ning katta toimeaine osakesi. Nimetatud tootmistehnoloogiat saab kasutada näiteks toimeainet prolongeeritult vabastavate tablettide valmistamisel.

Tableteerimisel kasutatakse tablettide pressimise masinaid KILIAN S250 SMART ja FETTE 1200, kus kasutatakse magneesiumstearaadi kuivpihustamise tehnoloogiat tableti kokkupressimispiirkonda. See tehnoloogia tagab stabiilsed pressimisparameetrid ning samas aitab vähendada vajadust lisada tablettide koostisesse abiainena lubrikante.

Seadmete erinevad eemaldatavad formaadiosad võimaldavad valmistada ja pakendada erineva suurusega ja konfiguratsiooniga tablette.

Tablettide tootmisel ja pakendamisel saavad töötada samaaegselt kolm tootmisliini.

Paralleelselt tabletteerimisega toimub tablettide automaatne pakendamine ribapakendisse pakendamisliinil Marchesini MST 300. Ribapakendid liiguvad mööda konveierit pakendamisliinile Marchesini MA 100, mis pakendab esmase pakendi kartongkarpidesse.

Tablettide pakendamine tuubidesse ning korgiga sulgemine teostatakse pakendamisliinil Gordic F60 ning toimub samaaegselt koos tableteerimisega tableti pressil.

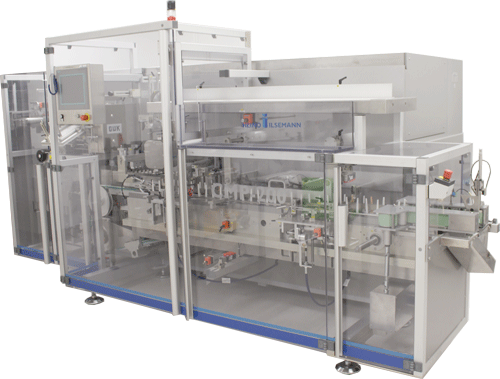

Heino Ilsemann BMP-250R pakendamisliinil on võimalik pakendada tabletid fooliumblistrisse (Alu/Alu) või blisterpakendisse Alu/PVC, Alu/PVDC. Blistritesse pakendamise liin on konveieri abil ühendatud pakendamisliiniga Heino Ilsemann CMP-200, mis pakendab blistrid teisesesse pakendisse.

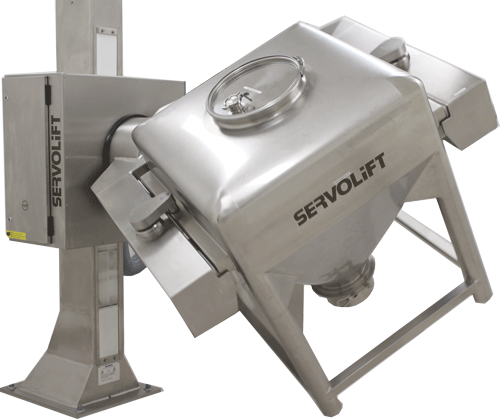

The Servolift Lifter mixing system including BIN blender (or IBC , an intermediate container) is the best way to process, mix and transport any powdered product of less than 4000 liters. The mixing process is very simple: the products are mainly ground and mixed by continuous rotation until a homogeneous mixture is obtained.

The Servolift Lifter mixing system including BIN blender (or IBC , an intermediate container) is the best way to process, mix and transport any powdered product of less than 4000 liters. The mixing process is very simple: the products are mainly ground and mixed by continuous rotation until a homogeneous mixture is obtained. The technical solutions of the Innojet VENTILUS 200 granulator are designed to enable the processes of granulation, coating and drying of microparticles and are based on fluid bed technology with given radial and tangential flow of process air that leads to a spiral flow direction of the product.

The technical solutions of the Innojet VENTILUS 200 granulator are designed to enable the processes of granulation, coating and drying of microparticles and are based on fluid bed technology with given radial and tangential flow of process air that leads to a spiral flow direction of the product. The S250 Rotary Tablet Press SMART Romaco Kilian is designed in accordance with the basic requirements of the pharmaceutical industry and is suitable for pressing of any powdered tablet mixture.

The S250 Rotary Tablet Press SMART Romaco Kilian is designed in accordance with the basic requirements of the pharmaceutical industry and is suitable for pressing of any powdered tablet mixture. The rotary tablet press Fette P 1200 is a productive single-flow tablet press for laboratory and pilot purposes. Fette P 1200 is a modular system that allows for quick change-over of the equipment when changing the format parts. The equipment includes an integrated lifting device for rapid change of the rotor with a mechanical fastening system, which allows the equipment to be positioned as a universal and reconfigurable construction.

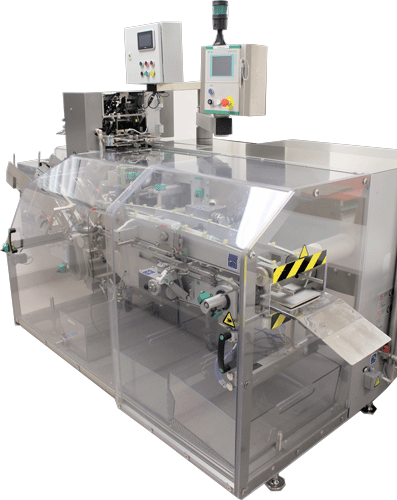

The rotary tablet press Fette P 1200 is a productive single-flow tablet press for laboratory and pilot purposes. Fette P 1200 is a modular system that allows for quick change-over of the equipment when changing the format parts. The equipment includes an integrated lifting device for rapid change of the rotor with a mechanical fastening system, which allows the equipment to be positioned as a universal and reconfigurable construction. GORDIC F-60 is a compact and flexible machine, which serves for the packaging of cylindrical tablets into plastic tubes. It is equipped with the SIEMENS S7 liquid crystal monitor, which displays operating instructions, error messages, the speed of packaging in tubes, etc. The machine is fully automated and protected from the external influences in accordance with the EU standards.

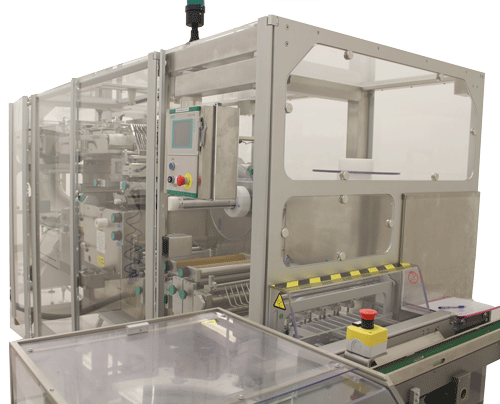

GORDIC F-60 is a compact and flexible machine, which serves for the packaging of cylindrical tablets into plastic tubes. It is equipped with the SIEMENS S7 liquid crystal monitor, which displays operating instructions, error messages, the speed of packaging in tubes, etc. The machine is fully automated and protected from the external influences in accordance with the EU standards. An automatic machine for packaging of solid dosage forms in strips , is universal, compact, easy to disassemble into individual units and to maintain.

An automatic machine for packaging of solid dosage forms in strips , is universal, compact, easy to disassemble into individual units and to maintain. The Marchesini MA 100 horizontal cartoner machine is made with modules that allow the implementation of three basic concepts: versatility, ergonomics and maximum efficiency in a small area.

The Marchesini MA 100 horizontal cartoner machine is made with modules that allow the implementation of three basic concepts: versatility, ergonomics and maximum efficiency in a small area. Ilsemann BMP 250 is a blister machine for thermoforming and cold forming. It has an ergonomic feed zone and is designed for automatic or manual feeding.

Ilsemann BMP 250 is a blister machine for thermoforming and cold forming. It has an ergonomic feed zone and is designed for automatic or manual feeding. The machine is designed for a wide range of packaging formats of any kind of pharmaceutical products, with or without a leaflet.

The machine is designed for a wide range of packaging formats of any kind of pharmaceutical products, with or without a leaflet.