Production

Our company portfolio was developed based on the requirements of effervescent tablet technology, taking into account real life cycle capabilities and the latest innovations in pharmaceutical equipment development.

The portfolio includes advanced dosage forms, such as effervescent tablets and orodispersible tablets for oral absorption, manufactured under special conditions, as well as chewable tablets and other solid dosage forms.

Our current drug portfolio also includes over-the-counter generics.

PharmaEstica Manufacturing OÜ also carries out private label and contract manufacturing projects.

Our capabilities allow us to produce a wide range of nutritional supplements and other specialty products. Our portfolio of nutritional supplements contain a variety of multivitamin and mineral combinations for adults, children and athletes, including herbal extract products. Food supplements may also be produced in the form of chewing gums.

| Trade name | Active substance(-s) and strength | Pharmaceutical form and package type | Indications | Type of Medicine | Registration | Subcontract manufacturing service |

|---|---|---|---|---|---|---|

| Upstinon | Acetylsalicylic acid 324 mg | Effervescent tablets in sachets | Alleviates mild pain and reduces fever | OTC | EE | |

| Asprovit C | Acetylsalicylic acid 400 mg, Ascorbic acid 300 mg | Effervescent tablets in tubes | Alleviates mild pain and reduces fever | OTC | RU | |

| Asprovit+С | Acetylsalicylic acid 400 mg, Ascorbic acid 300 mg | Effervescent tablets in tubes | Alleviates mild pain and reduces fever | OTC | EE | |

| Asprovit | Acetylsalicylic acid 500 mg | Effervescent tablets in sachets; tubes | Alleviates mild pain and reduces fever | OTC | EE | |

| Mucovit 600 | Acetylcysteine 600 mg | Effervescent tablets in sachets; tubes | Mucolytic agent for expectoration | OTC | EE | AZ, GE, KZ, KG, MD, TM, VN, UZ, UA, RU- in process |

| Mucovit 200 | Acetylcysteine 200 mg | Effervescent tablets in sachets; tubes | Mucolytic agent for expectoration | OTC | EE | AZ, GE, KZ, VN, KG, MD,TM, UZ, UA, RU- in process |

| Padevix | Dextromethorphan 7,5 mg, Paracetamol 300 mg | Effervescent tablets in sachets; blisters; tubes | Alleviates mild pain and reduces fever. Symptomatic treatment of cough | OTC | EE |

| Trade name | Composition | Dosage form | Recommended |

|---|---|---|---|

| PolliVital | Multivitamins with rutin | Orodispersible tablets | Multivitamins and bioflavonoid rutin enrich the daily diet. |

| OxiVital | Vitamin E – 10 mg a-TE, Vitamin C – 50 mg, Vitamin A – 450 μg-RE, Selenium 20 μg | Orodispersible tablets | Helps protect cells from oxidative stress and helps strengthen the immune system. |

| Resveratrol | Resveratrol 20 and 40 mg | Orodispersible tablets | A fortifying agent |

| PexVital | Multivitamins | Effervescent tablets | An additional source of vitamins. |

| SportActive | Vitamins, minerals | Effervescent tablets | For active lifestyle people and athletes during intense exercise. |

| Vitamin C | 100mg 1000mg | Chewing tablets Effervescent tablets | An additional source of vitamin C |

| Vitamin D3 | 600IU | Orodispersible tablets | An additional source of vitamin D3 |

Equipment and technologies

Our company manufactures medicines and food supplements in the following dosage forms: effervescent tablets, uncoated tablets, prolonged-release tablets, dispersible tablets, chewable tablets and other solid dosage forms.

The technological processes of tablet manufacturing are carried out under conditions of controlled temperature and humidity, which ensure the high quality of our medicines.

Direct compression is the main method used for production of tablets from powder mixtures or from micro-granules. Granulation is performed on Herbert Hüttlin Ventilus V200 granulator.

The capabilities of Herbert Hüttlin Ventilus V200 granulator enable us to obtain products with the desired properties by fluid bed granulation method and to perform coating of active substance particles used in the technologies of modified-release dosage forms. The KILIAN S250 SMART and FETTE 1200 tablet presses are used at the stage of tableting. The technology of dry injection of magnesium stearate into the tablet pressing area helps to reduce the content of sliding substances in tablets and to ensure stable pressing parameters.

Interchangeable sets with different removable format parts of the equipment allow the production and packaging of tablets with different sizes and configurations.

Three production lines can be used simultaneously for tablet manufacturing and packaging.

Tablet packaging is carried out in parallel with the tablet press operation. An automatic packaging line Marchesini MST 300 loads tablets into strips, which are then conveyed to the Marchesini MA 100 line for a secondary packaging.

The Gordic F60 packaging line is used to fill tablets into polypropylene tubes.

The Heino Ilsemann BMP-250R packaging line loads tablets into blisters, which are made of ALU/PVC/PVdC pocket forming film layer hermetically sealed with a layer of aluminium foil. The blister line is connected with a secondary packaging unit Heino Ilsemann CMP-200.

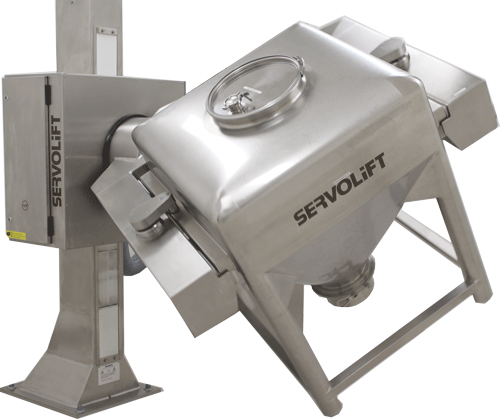

The Servolift Lifter mixing system including BIN blender (or IBC , an intermediate container) is the best way to process, mix and transport any powdered product of less than 4000 liters. The mixing process is very simple: the products are mainly ground and mixed by continuous rotation until a homogeneous mixture is obtained.

The Servolift Lifter mixing system including BIN blender (or IBC , an intermediate container) is the best way to process, mix and transport any powdered product of less than 4000 liters. The mixing process is very simple: the products are mainly ground and mixed by continuous rotation until a homogeneous mixture is obtained. The technical solutions of the Innojet VENTILUS 200 granulator are designed to enable the processes of granulation, coating and drying of microparticles and are based on fluid bed technology with given radial and tangential flow of process air that leads to a spiral flow direction of the product.

The technical solutions of the Innojet VENTILUS 200 granulator are designed to enable the processes of granulation, coating and drying of microparticles and are based on fluid bed technology with given radial and tangential flow of process air that leads to a spiral flow direction of the product. The S250 Rotary Tablet Press SMART Romaco Kilian is designed in accordance with the basic requirements of the pharmaceutical industry and is suitable for pressing of any powdered tablet mixture.

The S250 Rotary Tablet Press SMART Romaco Kilian is designed in accordance with the basic requirements of the pharmaceutical industry and is suitable for pressing of any powdered tablet mixture. The rotary tablet press Fette P 1200 is a productive single-flow tablet press for laboratory and pilot purposes. Fette P 1200 is a modular system that allows for quick change-over of the equipment when changing the format parts. The equipment includes an integrated lifting device for rapid change of the rotor with a mechanical fastening system, which allows the equipment to be positioned as a universal and reconfigurable construction.

The rotary tablet press Fette P 1200 is a productive single-flow tablet press for laboratory and pilot purposes. Fette P 1200 is a modular system that allows for quick change-over of the equipment when changing the format parts. The equipment includes an integrated lifting device for rapid change of the rotor with a mechanical fastening system, which allows the equipment to be positioned as a universal and reconfigurable construction. GORDIC F-60 is a compact and flexible machine, which serves for the packaging of cylindrical tablets into plastic tubes. It is equipped with the SIEMENS S7 liquid crystal monitor, which displays operating instructions, error messages, the speed of packaging in tubes, etc. The machine is fully automated and protected from the external influences in accordance with the EU standards.

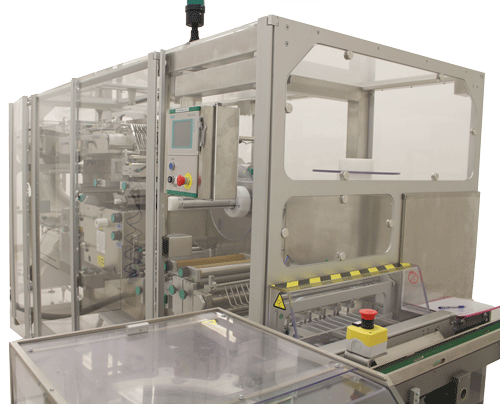

GORDIC F-60 is a compact and flexible machine, which serves for the packaging of cylindrical tablets into plastic tubes. It is equipped with the SIEMENS S7 liquid crystal monitor, which displays operating instructions, error messages, the speed of packaging in tubes, etc. The machine is fully automated and protected from the external influences in accordance with the EU standards. An automatic machine for packaging of solid dosage forms in strips , is universal, compact, easy to disassemble into individual units and to maintain.

An automatic machine for packaging of solid dosage forms in strips , is universal, compact, easy to disassemble into individual units and to maintain. The Marchesini MA 100 horizontal cartoner machine is made with modules that allow the implementation of three basic concepts: versatility, ergonomics and maximum efficiency in a small area.

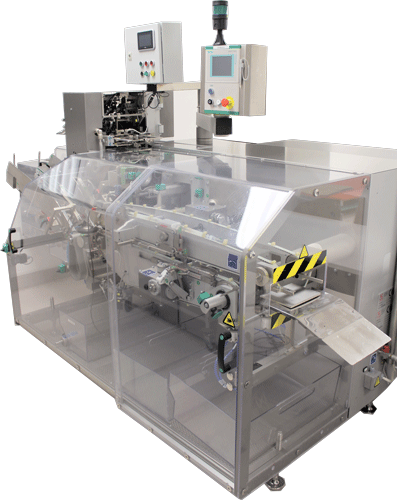

The Marchesini MA 100 horizontal cartoner machine is made with modules that allow the implementation of three basic concepts: versatility, ergonomics and maximum efficiency in a small area. Ilsemann BMP 250 is a blister machine for thermoforming and cold forming. It has an ergonomic feed zone and is designed for automatic or manual feeding.

Ilsemann BMP 250 is a blister machine for thermoforming and cold forming. It has an ergonomic feed zone and is designed for automatic or manual feeding. The machine is designed for a wide range of packaging formats of any kind of pharmaceutical products, with or without a leaflet.

The machine is designed for a wide range of packaging formats of any kind of pharmaceutical products, with or without a leaflet.